Slip Formed Pavements

Current practice for a concrete mixture is to require relevant strength and durability specifications, while also providing sufficient workability for the desired application. Producing a concrete mixture that meets all of these requirements can be allusive and highly iterative. Although tests exist to evaluate the strength and durability of a mixture, no test exists for evaluating the workability of concrete for slip formed pavement.

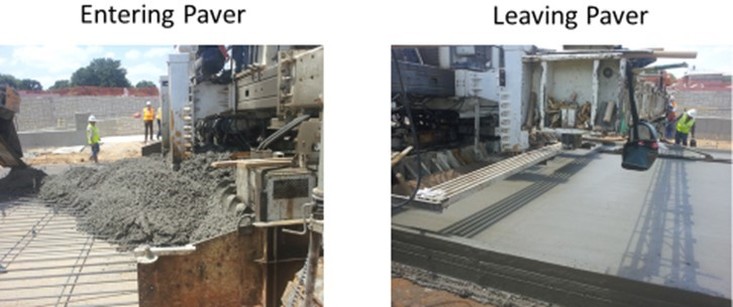

A concrete mixture for a slip formed pavement must be stiff enough to hold an edge after leaving the paver, but workable enough to be consolidated and surface finished. Historically, the workability of a concrete mixture was determined by experience because no known test could evaluation the stiffness and consolidation of a mixture simultaneously. To fulfill the need in the concrete pavement industry for a reliable slip formed pavement workability test, our team developed the Box Test. It is a simple and economical test method that attempts to evaluate the vibratory response of a concrete mixture and subsequently hold a vertical edge under its weight.

A concrete mixture for a slip formed pavement must be stiff enough to hold an edge after leaving the paver, but workable enough to be consolidated and surface finished. Historically, the workability of a concrete mixture was determined by experience because no known test could evaluation the stiffness and consolidation of a mixture simultaneously. To fulfill the need in the concrete pavement industry for a reliable slip formed pavement workability test, our team developed the Box Test. It is a simple and economical test method that attempts to evaluate the vibratory response of a concrete mixture and subsequently hold a vertical edge under its weight.

Evaluating Different Proportioning Techniques

After the Box Test was developed, our research team investigated some of the more popular aggregate proportioning methods and compared the workability performance of each mixture. Mixtures were designed with a fixed amount of paste but using different aggregate proportioning methods for the sole purpose of slip formed paving. With three sources of sand, three different sources of crushed stone, and two river gravel sources, we have test over 400 mixtures for the sole purpose of slip formed pavements. Many monumental findings have been made in the workability effects on the proportioning of aggregates. Click here for the full report. Also, information can be found at developed limits tab.

After the Box Test was developed, our research team investigated some of the more popular aggregate proportioning methods and compared the workability performance of each mixture. Mixtures were designed with a fixed amount of paste but using different aggregate proportioning methods for the sole purpose of slip formed paving. With three sources of sand, three different sources of crushed stone, and two river gravel sources, we have test over 400 mixtures for the sole purpose of slip formed pavements. Many monumental findings have been made in the workability effects on the proportioning of aggregates. Click here for the full report. Also, information can be found at developed limits tab.