SPECIFICATION FOR OPTIMIZED GRADED CONCRETE PAVEMENT

Introduction

After evaluating almost 500 concrete mixtures for slip formed pavements, our research team used the data to develop a specification for slip formed pavements for the state of Oklahoma. Below is the recommended specification for ODOT .

After evaluating almost 500 concrete mixtures for slip formed pavements, our research team used the data to develop a specification for slip formed pavements for the state of Oklahoma. Below is the recommended specification for ODOT .

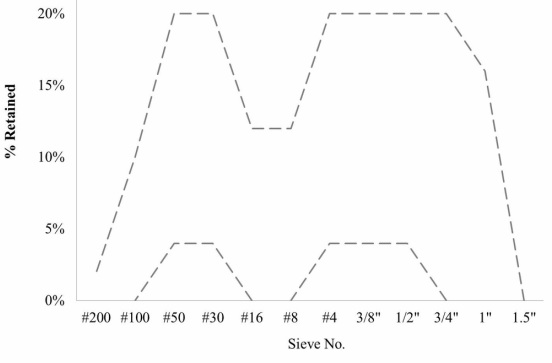

Figure shows the minimum and maximum limits.

Figure shows the minimum and maximum limits.

Mix Design and Proportioning

If the contractor provides a concrete mixture meeting the specifications for optimized graded concrete pavement (OGCP), the minimum cementitious content may be reduced to 470 lbs/yd3 [279 kg/m3].

Specification

To meet the optimized graded concrete pavement provision criteria, the batch weights, individual aggregate sieve analysis, SSD specific gravities of the aggregates, and other material information will be inputted into the OGCP spreadsheet. This OGCP spreadsheet can be found at the bottom of the page.

The specification requires the following:

· The combined gradation must be within the boundary limits for each sieve size.

· The total volume of coarse sand (#8-30) must be a minimum of 15%.

· The total volume of fine sand (#30-200) must be within 24% and 34%.

· Limit the flat or elongated coarse aggregate to 15% or less at a ratio of 1:3 according to ASTM 4791.

Gradation Tolerance

Make necessary adjustments to individual aggregate stockpile proportions during OGCP concrete production to ensure the gradation stays within ODOT requirements. If this is not possible then the minimum cementitious content in the mixture shall be increased to 517 lbs/yd3 (307 kg/m3).

If the contractor provides a concrete mixture meeting the specifications for optimized graded concrete pavement (OGCP), the minimum cementitious content may be reduced to 470 lbs/yd3 [279 kg/m3].

Specification

To meet the optimized graded concrete pavement provision criteria, the batch weights, individual aggregate sieve analysis, SSD specific gravities of the aggregates, and other material information will be inputted into the OGCP spreadsheet. This OGCP spreadsheet can be found at the bottom of the page.

The specification requires the following:

· The combined gradation must be within the boundary limits for each sieve size.

· The total volume of coarse sand (#8-30) must be a minimum of 15%.

· The total volume of fine sand (#30-200) must be within 24% and 34%.

· Limit the flat or elongated coarse aggregate to 15% or less at a ratio of 1:3 according to ASTM 4791.

Gradation Tolerance

Make necessary adjustments to individual aggregate stockpile proportions during OGCP concrete production to ensure the gradation stays within ODOT requirements. If this is not possible then the minimum cementitious content in the mixture shall be increased to 517 lbs/yd3 (307 kg/m3).

| ogcp_spreadsheet.xlsx | |

| File Size: | 1015 kb |

| File Type: | xlsx |

| ogcp_spreadsheet_metric.xlsx | |

| File Size: | 1016 kb |

| File Type: | xlsx |